Dilatation seals, also known as expansion joints or expansion seals, are essential components used in various engineering and construction applications to accommodate the movement, thermal expansion, vibration, and other dynamic forces in structures and systems. These seals serve a critical function in preventing damage and ensuring the structural integrity and safety of a wide range of infrastructure, from buildings and bridges to pipelines and industrial machinery.

A comprehensive description of dilatation seals involves understanding their purpose, types, materials, design considerations, and applications. Here is a detailed explanation of these important aspects:

1. Purpose of Dilatation Seals:

Dilatation seals are primarily designed to compensate for the changes in dimensions and movements that occur due to factors such as temperature fluctuations, seismic activity, mechanical vibrations, and settling of structures. Without proper expansion joints, these movements could result in structural damage, such as cracks, leaks, or even catastrophic failure. Therefore, the primary purpose of dilatation seals is to provide a flexible and controlled way to absorb and distribute these forces, ensuring the long-term durability and safety of structures and systems.

2. Types of Dilatation Seals:

There are several types of dilatation seals, each tailored to specific applications and movement requirements:

a. Movement Expansion Joints: These are used to accommodate linear movements in structures, such as buildings, bridges, and roadways. They are designed to handle both horizontal and vertical expansions and contractions.

b. Pipe Expansion Joints: These are used in pipelines to absorb axial, lateral, and angular movements, as well as vibrations. They are crucial in industries like petrochemical, energy, and water supply.

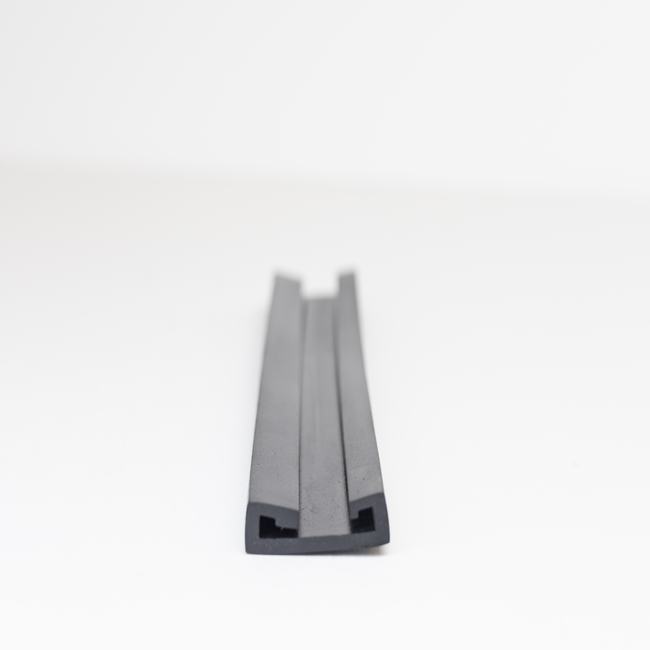

c. Rubber Expansion Joints: Made of elastomeric materials, rubber expansion joints are used to absorb movement in various applications, including HVAC systems, plumbing, and industrial machinery.

d. Metal Expansion Joints: Designed for high-temperature and high-pressure environments, metal expansion joints are commonly used in industrial processes, power plants, and chemical plants.

e. Fabric Expansion Joints: Fabric expansion joints are lightweight and flexible, making them suitable for gas and air ducting systems, as well as other low-pressure applications.

3. Materials:

Dilatation seals are constructed from a variety of materials, depending on the specific requirements of the application. Common materials used include rubber, neoprene, EPDM, PTFE, stainless steel, carbon steel, and various fabric composites. The choice of material is critical to ensure the seal’s durability, chemical resistance, and ability to withstand temperature extremes.

4. Design Considerations:

The design of dilatation seals involves several important considerations, including:

a. Movement Range: Determining the maximum and minimum expected movement in the system to select the appropriate type and size of expansion joint.

b. Pressure and Temperature: Considering the operating conditions, including pressure and temperature, to choose materials and design features that can withstand these conditions.

c. End Connections: Selecting the appropriate end connections (flanged, threaded, grooved, etc.) for easy installation and compatibility with existing systems.

d. Reinforcement: In cases of high pressure or large movements, reinforcements like internal liners or arches are often integrated into the design.

e. Chemical Resistance: Ensuring that the chosen material is compatible with the substances it will come into contact with.

5. Applications:

Dilatation seals find applications in a wide range of industries and structures, including:

a. Building Construction: Bridges, highways, and buildings to accommodate thermal expansion and seismic movements.

b. Pipeline Systems: To prevent leakage and structural damage in pipelines for water, gas, oil, and chemicals.

c. Industrial Processes: In industrial machinery, power plants, and manufacturing facilities to absorb vibrations and movement.

d. HVAC Systems: In heating, ventilation, and air conditioning systems to isolate vibrations and control thermal expansion.

e. Marine and Offshore: Used in shipbuilding and offshore structures to handle dynamic forces and movements caused by waves and tides.

In summary, dilatation seals, or expansion joints, are indispensable components in engineering and construction, enabling structures and systems to withstand the forces of nature, temperature fluctuations, and dynamic movements. Their design, material selection, and installation are critical for ensuring the safety, longevity, and functionality of diverse applications across various industries.